EXAMPLES OF INDUSTRIAL TRANSITION TO CIRCULAR ECONOMY MODELS: NEW MATERIALS FOR TRANSPORT AND CONSTRUCTION

FIREMAT (and related European “C2CC project”): developed new materials and processes, paying attention to environmental impacts and recyclability. In particular FireMat developed fire-resistant composite materials for weight reduction in transport sector and constructions, studying a mineral fiber which (contrary to carbon fiber) can be reused many times, by re-melting it at the end of its life, obtaining a fiber with the exact original mechanical performances. ENEA coordinated the development and construction of:

- a fire-proof turbine-bonnet for an helicopter. At the moment, only virtual validation by modeling was done, but in perspective having produced a 1:1 prototype opens the door to tests on Zefhir helicopter (developed by Curti) itself.

- a carbon-look exhaust pipe for the same helicopter, with a weight which is only 30% of the steel equivalent.

- a fire-resistant panel, for thermal insulation a interesting aesthetical appearance.

These innovations might increase flight autonomy and less CO2 production in the aeronautical sector, but also for marine and surface transports. On the other hand, developed panels seem particularly interesting for constructions.

GEOPOLYMER LAB

This is a pilot line designed to produce long carbon fiber reinforced inorganic polymer matrix materials.

Mixing of reactive powders with water-based activating solution and refractory powders in an orbital mixer, https://www.istec.cnr.it/en/research/technological-laboratories/formature-laboratory/planetary-centrifugal-mixer/, that mixes and disperses different materials by deaerating them.

Impregnation of carbon fiber fabrics, overlapping layers – preparation by vacuum bagging. Last step: heat treatment in an inert atmosphere that transforms the inorganic polymer matrix into refractory ceramic glass.

MICROSCOPY AND THERMAL ANALYSIS LABS

The microscopy lab offers the possibility of investigating materials by morphology, phase distribution, microstructure, porosity, defects, chemical-physical composition, crystallographic aspect. https://www.istec.cnr.it/en/research/technological-laboratories/microscopy/scanning-electron-microscopes/

Electron microscopy allows the observation of objects with an expansion 1000 times higher than optical microspopy, thanks to an electron beam that interacts with the sample.

The lab is equipped with a Field Emission Scanning Electron Microscopy (FESEM) and a Variable Pressure/ Environmental Scanning Electron Microscopy (ESEM).

The thermal analysis lab assesses materials’ physical property, which is measured in function of time / temperature: the substance is subjected to a controlled temperature program (heating, cooling, isotherm). It is equipped for different types of analysis: differential scanning calorimetry, fleximetry, softening, melting, dilatometry, thermogravimetric analysis. https://www.istec.cnr.it/en/research/technological-laboratories/thermal-analysis-laboratory/

FLEXURAL TESTS

Certimac performed experimental tests on 2 types of innovative materials:

- Fiber Metal Laminates (FMLs);

- Composite systems consisting of three different layers: a ceramic tile, an insulating felt and a prepreg composite material

The experimental campaign was performed in order to evaluate the improvement in the mechanical performances of these innovative products with respect to traditional systems. To this aim, three-point bending tests were carried out to assess the increase in the mechanical properties in terms of flexural strength and ultimate strain. In parallel, in order to evaluate the adhesion between the different layers, the tensile strength perpendicular to faces was determined.

ARTIFICIAL AGING TESTS

Certimac carried out durability tests to assess the performance of the innovative materials after artificial aging cycles.

Tests on unconditioned samples were implemented to quantify the reference parameters. Then, the same tests were performed on artificially aged samples, in order to measure the performance after aging and evaluate the decay of performance.

In detail:

- for basalt composite materials and FML, the focus was on salt fog in an appropriate climatic chamber (60 samples for 1000 hours, checking temperature, humidity, salts’ concentration)

- for multilayer materials (ventilated facades), the focus was on freeze/thaw aging in a climatic chamber able to perform thermal cycles from -20 °C to + 20 °C and immersion in water.

AERONAUTICAL COMPONENTS

MUSP deals with the engineering of demonstrators. Within the FIREMAT project MUSP developed one for the construction sector and 1 component for the aeronautical sector.

In particular, the creation of a hood for the Zefhir helicopter, in FML material. MUSP carried out the development of material models: thanks to a numerical modeling path, MUSP obtained the data necessary for the modeling of the component in 1:1 scale and achieved the optimization of the composite playbook. In the final phase MUSP dealt with the sizing of the demonstrator subjected to operational stresses (focus on structural optimization to combine strength and lightweight).

VENTILATED FACADE PANELS

As for ventilated facade panel demonstrator: use of preceramic prepreg, basalt, felt combined with the aesthetic effect of stoneware in the outer layer.

MUSP tested this composition to find the plybook able of meeting the requirements in terms of structural performance. Digital twins of the experimental tests were carried out by reproducing the identical test conditions and a sequence of simulations was prepared to perform the data matching of the experimental results.

A detailed model allowed to optimize the position and supports of the panel, identifying the position able to minimize the deflection of the panel subjected to the expected loads.

MUSP prepared a model of the panel and supporting substructures to size in detail the constructive solution of the demonstrator.

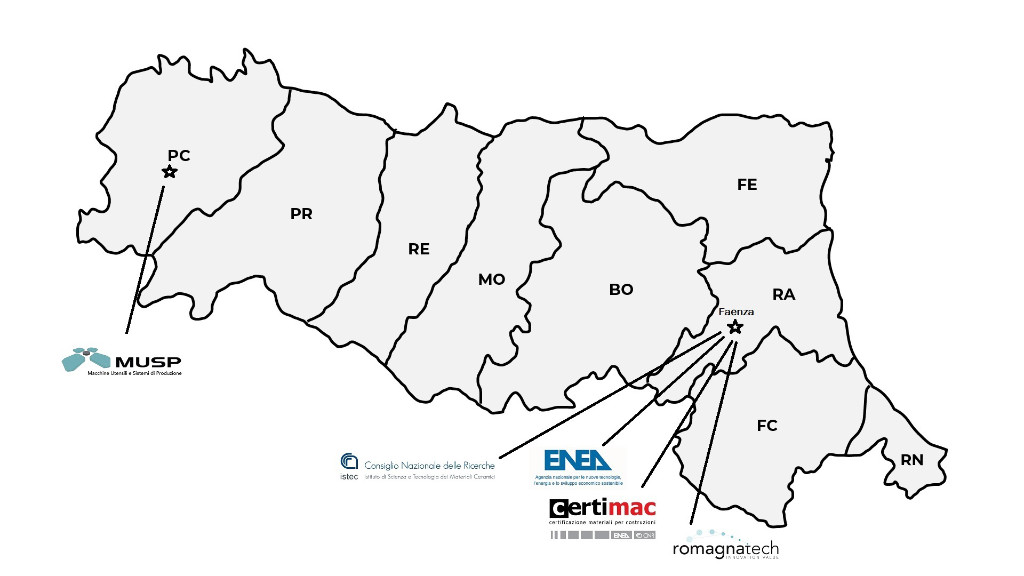

MUSP – Piacenza Tecnopole’s virtual tour